YBP Home > Portfolio > Industrial Design > Printers<

Printers

Ink Jet Printer

Client:

Qume Corporation

Background

The consumers' need was for an inexpensive, small, quiet, yet quick printer to compliment the advances made in computer software. The "graphic" printers available to the public are either cheap (but not letter quality) such as matrix, or laser printers with high resolution and also high costs. This printer offered the consumer a reasonably priced, letter quality, printer with graphics capabilities.

Goals:

Design: Improve appearance of previous products while retaining the product branding.

Manufacturing: A primary requirement was to design a printer with minimum handling during manufacturing.

Accomplishments:

This printer won a national Industrial Design Excellence Award. It was the first time a computer peripheral gained this level of recognition. And it confirms my philosophy that team synergy leads to significantly better results. This printer was developed by a consultant, John Jamieson, and myself. John had been an employee so was familiar with the design language we were using allowing us to take the design to a new level. The elegant "high tech" appearance is revolutionary for an OEM (Original Equipment Manufacturer) supplier where the usual approach is to fit in with the furniture. This product takes OEM design to a level not thought possible.

The test of a really good designer is if s/he can resolve the practical issues to an extent that they become part of, or better yet, enhance the design goals.This printer consist of only four components. All parts are designed to be snap mounted into the cast base, yet there is no sacrifice to the overall elegant design.

Another example is the paper output tray/access door. Semantically speaking, the use of black polycarbonate has become synonymous with "high tech", electronic products, but it's still rarely used in the office environment. Not only does PC deliver the subconscious message desired, but it also has the engineering qualities required. Adding the partially raised spheres solved many issues. Functionally, they reduce the static of the paper as it ejects from the printer. Sculpturally, they add interest to the product. Psychologically, they add a playfulness. Physically, they make it easier to pick up the paper.

Ink Jet Printer Control Panel

Client:

Qume Corporation

Goals:

Design: Improve appearance of previous products while retaining the product branding.

Manufacturing: A primary requirement was to design a printer with minimum handling during manufacturing.

Accomplishments:

A great deal of effort went into designing the human interface between the more sophisticated commands available with this module and the requirement that its use be self-explanatory.

The LEDs on the control panel instruct the user in such simple tasks as to refill the paper tray or clear a paper jam. The small buttons are to stop and start the printing process, and advance the paper.

Ink Jet Printer Detail

Client:

Qume Corporation

Goals:

Design: Improve appearance of previous products while retaining the product branding.

Manufacturing: A primary requirement was to design a printer with minimum handling during manufacturing.

Accomplishments:

The power on switch was originally going to be located in the back of the printer, which would not be convenient for the end user. (This, after all, was one of the first desktop printers so the end user would turn it on and off frequently.) The engineer was adamant that he could not move it to the top. As we worked together, I solved some of his issues by changing my design. A few days later, he announced he had solved how to design the components so the power button would be more accessible.

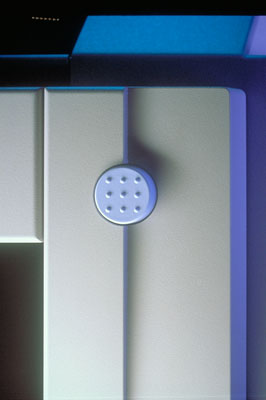

Ink Jet Printer Venting

Client:

Qume Corporation

Goals:

Design: Improve appearance of previous products while retaining the product branding.

Manufacturing: A primary requirement was to design a printer with minimum handling during manufacturing.

Accomplishments:

The design challenge is to combine the intuitive sculptural qualities inherent in the product's purpose with the functional elements necessary to successfully mass produce and market it.

As with the other products for this company, product semantics was an integral force in the product's expression. The graduating vents of the heat sink are a metaphorical expression of dissipating heat.

LaserTEN Printer

Client:

Qume Corporation

Background

Our Taiwanese engineers built a laser printer model using a Japanese engine and an existing computer interface module (designed for a dot matrix printer) that they hung off the top right side. The model was a square box with the module and its cord suspended in air when the end user opened the printer to service it. The interface module on the top half of the printer, and the fan in the bottom half, determined the extreme height of the model.

Goals:

Design: Design a laser printer incorporating look & feel of QVT 1 terminal.

User interface: Make the use and service easy for the end user.

Engineering: Reduce the overall height of the printer.

Incorporate the existing computer interface module.

Marketing: Complete the design and a working model in 3 months for a computer show.

Accomplishments:

This was the most challenging design done for Qume and I completed it in record time.

I used the QVT’s “shrink wrap” design vocabulary to tie in the printer and similar control panel, and venting details. A user interface detail that indicates a panel can open is the spherical thumb indentations. To clear a paper jam, I placed a large wedge shaped lever on the top with the same thumb indentation.

Flying to Taiwan, I worked with the engineers to reduce the overall height by six inches. I moved the interface module to the back bottom half of the printer. By splitting the printer in the back around the module, I gained several inches in height. I found a smaller fan, and then increased the venting in the back and sides to provide the necessary cooling.

I completed the housing engineering drawings and flew to Japan to work with the laser engine engineers to build the working model. We complete the model in 3 weeks by employing a very different working process than they were accustomed to. I took the parts that had few conflicts and had them modeled first, and gradually worked my way to the parts that interfaced with other parts. I overcame the engineers’ language barrier by illustrating the design issues on the blackboard and the novelty of my gender didn't seem to be an issue.

LaserTEN Control Panel

Client:

Qume Corporation

Goals:

Design: Design a laser printer incorporating look & feel of QVT terminals.

User interface: Make the use and service easy for the end user.

Engineering: Reduce the overall height of the printer.

Incorporate the existing computer interface module.

Marketing: Complete the design and a working model in 3 months for a computer show.

Accomplishments:

The control panel has similar details as the QVT 1 terminal with the use of different levels to emphasize the LED lights and spherical buttons. Small details like a positive instruction of what to do when an LED lights, for example, “Replace toner” not “Toner is empty” assist the end user.

LaserTEN Printer Detail

Client:

Qume Corporation

Goals:

Design: Design a laser printer incorporating look & feel of QVT terminals.

User interface: Make the use and service easy for the end user.

Engineering: Reduce the overall height of the printer.

Incorporate the existing computer interface module.

Marketing: Complete the design and a working model in 3 months for a computer show.

Accomplishments:

Many panels on the printer opened for service. I used thumb indentations to indicate which panels opened. Static electricity causes paper to stick to a surface after it is printed. The small half circles make it easy to pick up either 11 or 14 inch paper.

Laser Printer Vents

Client:

Qume Corporation

Goals:

Design: Design a laser printer incorporating look & feel of QVT terminals.

User interface: Make the use and service easy for the end user.

Engineering: Reduce the overall height of the printer.

Incorporate the existing computer interface module.

Marketing: Complete the design and a working model in 3 months for a computer show.

Accomplishments:

I used a shorter fan to reduce the height, but that meant increasing the venting in the back and sides. I incorporated thin slots with the fat functional ones to relate to the QVT terminal's design vocabulary.